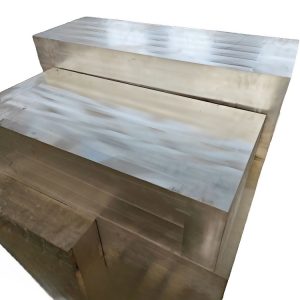

Name:Soluble magnesium alloy

Specifications:≤Φ300mm

Technical Parameter:

| Technical Parameter | ||||||

| Name | Tensile strength(Mpa) | Yield strength(Mpa) | Elongation rate

(%) |

HBW | Dissolution conditions | Rate

mg/(cm².h) |

| DM01 | ≥220 | ≥170 | ≥14 | ≥55 | 50℃/0.84%KCL | 30-50 |

| DM01 | ≥270 | ≥180 | ≥13 | ≥55 | 50℃/0.84%KCL | 40-80 |

| DM03 | ≥240 | ≥190 | ≥7 | ≥60 | 43℃/0.05%KCL | 50-70 |

| DM04 | ≥260 | ≥200 | ≥5 | ≥60 | 43℃/0.05%KCL | 60-80 |

| DM05 | ≥300 | ≥210 | ≥5 | ≥65 | 43℃/0.05%KCL | 30-50 |

| DM06 | ≥350 | ≥250 | ≥3 | ≥90 | 50℃/0.84%KCL | 40-70 |

| DM07 | ≥190 | ≥120 | ≥30 | ≥50 | 93℃/3%KCL | 20-70 |

| DM08 | ≥280 | ≥190 | ≥14 | ≥60 | 93℃/3%KCL | 40-80 |

| DM09 | ≥300 | ≥200 | ≥15 | ≥60 | 93℃/3%KCL | 90-140 |

| DM10 | ≥400 | ≥300 | ≥3 | ≥100 | 93℃/3%KCL | 20-40 |

| DM11 | ≥300 | ≥210 | ≥14 | ≥70 | 93℃/3%KCL | 5-10 |

| DM12 | ≥440 | ≥340 | ≥3 | ≥100 | 93℃/3%KCL | 10-30 |

Notes:Material properties can be adjusted according to customer requirements

Dissolvable alloys are essential materials that have been formulated to provide various corrosion rates and mechanical property in a controlled manner. This material is widely used in oil & gas industry. Customized to your specification with a quick turnaround, our process of making dissolvable magnesium alloys is produced through alloying, casting, and extrusion along with a special program of heat treatment for different alloys to yield what is expected.

评价

目前还没有评价